Neon signs and sculptures are made of bent glass tubes and filled with inert gas. They're usually used for advertising purposes but due to their brilliant colors, many people display them in their homes as a piece of art!

When an electric charge hits the electrodes in the tubes, the electrons flow through the gas making its atoms dance around and glow! The type of gas and col.or of the glass determine the color of the light. The combination of colored glass tubes and type of inert gas can produce up to 120 different colors!

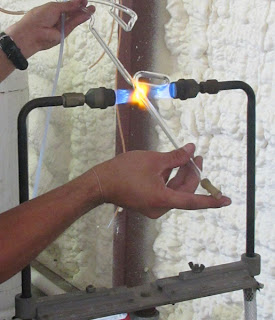

To shape the tube, glass benders use a glass blowing technique. Following a pattern drawn on a fire-resistant sheet, they mark where they have to bend the tube with a marker. Then they heat each spot on a propane flame blazing 1200 degrees F. Within about half a minute, the glass softens enough to be pliable. They gently bend the tube while blowing into a rubber tube attached to the uncorked end to restore the original diameter of the tube.

With each bend, they check the shape against the pattern, every so often pressing a wooden block along the tube to equalize the width. After shaping, they cut off the excess and rub the coloring powder off the ends of the tubes. Now they can attach glass casings which contain electrodes. They fuse an electrode to each end of the tube using a propane hand torch and a flexible latex blowing tube. They seal the glass around one electrode, but leave the other one open.

Then, the glass benders create a thin tube with a small bubble that will act as a passageway to the open electrode (known in the industry as a "tubulation"). They fuse this tube to the electrode and then carefully inject a drop of mercury into the open end of it. This mercury will react with Argon gas and make the neon signs glow much brighter.

Using an end torch, they fuse the open end of the tubulation to a long glass tube leading to a pumping system. They connect the electrodes to the system and then power it up. The pump vacuums out the air then injects the gas. To trap the gas inside the tube, they use the crossfire burner to remove the bubble and seal off the open electrode, making sure the drop of mercury has descended into it first. They then dip the back of the sign into black paint, which makes the lettering or design stand out. They use a brush to spread the coat evenly and remove the excess.

Next, they'll light up the sign at high voltage for a half hour. This will dry the paint and more importantly transform the liquid mercury into vapor that spreads throughout the sign. Using transparent clips, assemblers mount the sign onto a black Plexiglas background to make it stand out even more.

Finally, they connect the protruding electrode wires to a transformer, which converts the current needed to light up the sign. And voila! Custom Neon Signs make great gifts and look awesome on your wall.

Source: Neon and More How Neon Signs Are Made

When an electric charge hits the electrodes in the tubes, the electrons flow through the gas making its atoms dance around and glow! The type of gas and col.or of the glass determine the color of the light. The combination of colored glass tubes and type of inert gas can produce up to 120 different colors!

|

| Bending the glass tubes with a flame |

|

| Checking the bent glass against the pattern |

Then, the glass benders create a thin tube with a small bubble that will act as a passageway to the open electrode (known in the industry as a "tubulation"). They fuse this tube to the electrode and then carefully inject a drop of mercury into the open end of it. This mercury will react with Argon gas and make the neon signs glow much brighter.

Using an end torch, they fuse the open end of the tubulation to a long glass tube leading to a pumping system. They connect the electrodes to the system and then power it up. The pump vacuums out the air then injects the gas. To trap the gas inside the tube, they use the crossfire burner to remove the bubble and seal off the open electrode, making sure the drop of mercury has descended into it first. They then dip the back of the sign into black paint, which makes the lettering or design stand out. They use a brush to spread the coat evenly and remove the excess.

|

| Finished Product! |

Finally, they connect the protruding electrode wires to a transformer, which converts the current needed to light up the sign. And voila! Custom Neon Signs make great gifts and look awesome on your wall.

Source: Neon and More How Neon Signs Are Made

I wanted to thank you for this excellent read!! I definitely loved every little bit of it. I have you bookmarked your site to check out the new stuff you post. Neon light signs

ReplyDeleteNice blog and absolutely outstanding. You can do something much better but i still say this perfect.Keep trying for the best. Neon light signs

ReplyDeleteI really impressed after read this because of some quality work and informative thoughts . I just wanna say thanks for the writer and wish you all the best for coming!. Graduation Yard Signs in texas

ReplyDeleteI have read a few of the articles on your website now, and I really like your style of blogging. I added it to my favorites blog site list and will be checking back soon. Please check out my site as well and let me know what you think. custom neon light sign

ReplyDelete